CMM-Manager 2023 HF1

Version 2023 HF1 (12.3.1.9402)

Release Date: 01/11/2024

Required SSC Date: 01/01/2024 or later

General Information

This hotfix release is a full standalone release and will overwrite any existing 2023 installation

Bug Fixes

[1] Error when connecting or homing with IMUSB box

[2] Hole pattern paths deleted after running Operation Plan

CMM-Manager 2023

Version 2023 (12.3.1.9387)

Release Date: 12/22/2023

Required SSC Date: 01/01/2024 or later

1. Supported Operating Systems

- Windows 11 Pro or Enterprise

- Windows 10 Pro or Enterprise

* Windows 7 or 8 may still work, but not officially supported or tested

* CAD Converter 2023 or later no longer supports 32-bit OS, but CAD Converter 2022 can be used with CMM-Manager 2023 on 32-bit OS

2. Language Support

- English, Chinese, Czech, French, German, Italian, Japanese, Polish, Spanish

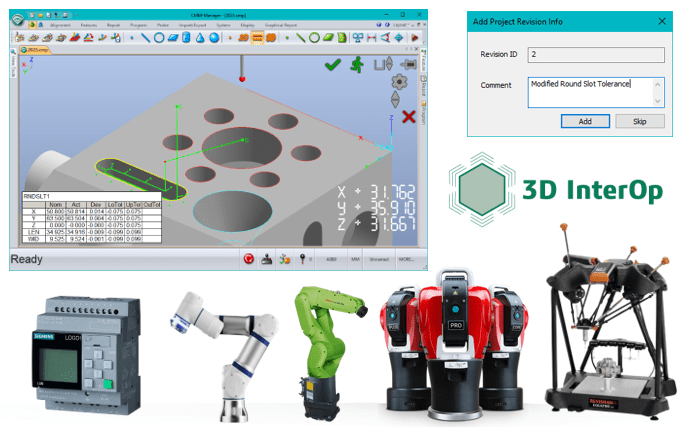

3. New Automation Software - QxAutomation-Manager

- Simple yet powerful solution for automation integration with CMM-Manager

- Intuitive UI for configuration, testing and operation

- Allows a maximum of 255 programs

- Supported protocols:

- Modbus TCP/IP Server

- Modbus TCP/IP Client

- Generic, Fanuc, Siemens

- Socket TCP/IP Client

4. Added support for Renishaw Equator Gauging System

- Supports full functionalities including CMM calibration for Equator

- Allows one program to be used for calibraiton, mastering and measuring

- Supports VB Script variable for mode selection

5. Added support for API Laser Tracker

- Supports API Radian Core/Plus/Pro models

- Supports various targets including SMR, Nest and vProbe

- Supports auto stability trigger and auto probe comp point collection

- Supports Jog, Go To and Leap Frog operations

6. Usability Improvements

- Added optional simplified CAD measurement interface for quick programming

- Made Program database right click menu context sensitive

- Added shortcut keys in the Program database for Copy, Paste, Cut, Find, Select All

7. Reporting Enhancements

- Allows to add report notes from Report database right click menu

- Allows multi-select Cloud features for Report Cloud Operation - Allows to include header and customer data fields at top of each report page

- Allows output of report title in DDE operation

- Allows to expand/collapse all report database window - Changed report preview display to higher contrast colors

- Improved drag-n-drop behavior in Report database

- Auto switch to Report database when creating a new graphical report

- Fixed: buildup of background Excel instances caused issue with paste address function in DDE operations

- Fixed: dashed lines for tolerance band did not show correctly in graphical report

- Fixed: Distance and Angle Between batch reporting only applying nominal values to first report output

8. Path Planning Enhancements

- Increased default clearance distance for path planning to 6.0 mm

- Added preference for rectangular vs circular for 5-axis plane measurement

- Fixed: link path issue in certain cases

- exit point from previous feature was too far out than needed

- Fixed: Verify did not create approach path if the first command was a 5-axis move

- Fixed: find Hole paths for Relative Measure could be created on wrong side of the feature

9. Client Monitoring App Enhancements

- Added tracking joystick motion as well as DCC motion

- Added option to resize dashboard tiles

- Fixed: DST issue in utilization calculation

10. Other Enhancements

- [1] Added new operation to allow sending I++ DME commands directly

- [2] Added Construct Point - intersection of (curve) cloud and plane/line

- [3] Allows to open associated program operation from Feature dialog

- [4] Keeps Furniture shown when using Place CAD command

- [5] Changed circular plane size definition from radius to diameter

- [6] Allows to set VB Script variables via command line argument - [7] Project revision history is now saved in file with optional comments

- [8] Improve ISO 10360 Probing Test - Allows to retrieve/input temperature info - Allows to output raw data

11. Driver Updates

- B&S Sharpe2 - COM port communication issue with USB to Serial adapter

- Faro Arm - TP20 trigger not detected reliably on Faro USB Arm

- Mitutoyo UC - Allow smaller pitch for SP25 unknown scan

- Fixed SP25 calibration output not scaled to Scale Factor

- Fixed software crash upon connection due to unexpected PHC response

- UCC Direct 2.0 - Fixed failure to send tool offset to UCC when re-connecting

- UCC I++ - Fixed software crash when doing I++ Sync with UCCserver that contains incompletely defined tools

- UCC Manual - Add support for UCC manual controller (MMI-2)

- Zeiss C99 - Allows to set joystick backoff distance

12. Bug Fixes

- [1] Edge/Angle points did not simulate or verify when using the simulate/verify function

- [2] Edge Point could show false error "two vectors are not perpendicular"

- [3] 2D scan feature location should not be projected to working plane

- [4] Edge Points in Points page sometimes did not snap points to the nearest edge

- [5] Probe Assembly dialog always shown in 3 decimal places even for inch

- [6] No verify button for Manual Measure Hole Pattern

- [7] Furniture did not stay hidden across sessions

- [8] No prompt to save project file upon closing with changes made to graphical report

- [9] Probe display incorrect during probe change (higher than it is)

- [10] Operation dialog shown on main monitor when CMM-M was running on second monitor

- [11] Help desk file export did not include files in all subfolders

- [12] Line-Circle intersection did not display points when axis line was used

- [13] Re-Boundary CAD surfaces on some models could cause software crash

- [14] Exported DXF Curves could not be opened in Fusion 360 / Autodesk

- [15] Not all features translate after cut/paste

- [16] Certain STEP model dimension became much larger when imported

- [17] SP25 scan program execution could use wrong approach and backoff distance

- [18 ]Selecting multiple features for construction may cause software crash

- [19] Wrong T deviation output when actual and nominal ref. frames were different

- [20] Homing in SFL without configuration file would cause the software to freeze

- [21] Certain Construct Point operation in a program could cause software crash upon file close

- [22] Failed to close programs with collapsed Program Groups containing disabled Get Probe Assembly operations

- [23] Default Vision layouts included incorrect DRO window

- [24] Error constructing mid-plane of two circular planes

- [25] Construct Bestfit Plane probe comp direction could be wrong when PCS Z-axis was inverse of nominal plane direction

- [26] Convert Excel to CSV may fail due to non-existent cached file path

- [27] Gasket scan not working properly in INCH mode

- [28] Ellipse fitting issue with probe comp

- [29] Background was not white when printing the display window

--End