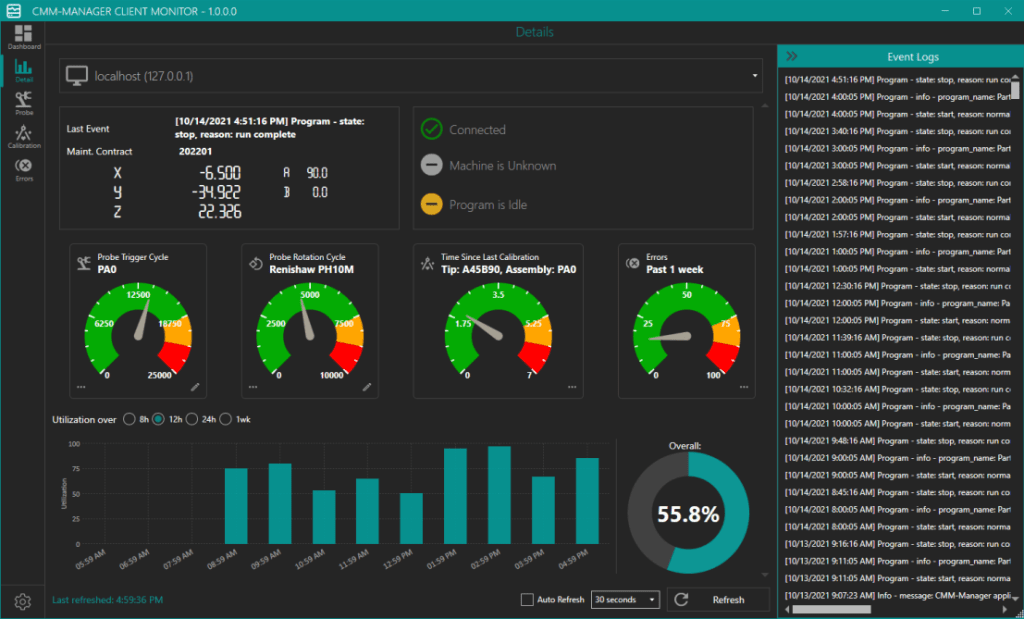

The CMM-Manager Client Monitoring App monitors and displays useful information in real-time including CMM usage / utilization, program running state, report pass / fail status, error events, probe rotation and trigger cycles, tip calibration status and more. Remotely monitoring the health and status of your coordinate measuring machine (CMM) is a smart move, especially if you want to reduce downtime, catch issues early, and maintain high throughput in quality control.

✅ Why You Should Monitor CMMs Remotely

🛠️ Preventive Maintenance – Monitor errors like axis drift, probe crashes, or servo errors before they become major problems. Receive alerts on conditions that signal wear or misalignment.

🕒 Minimize Downtime – Get notified if the machine faults, stalls, or sits idle unexpectedly. Great for lights-out manufacturing or high-mix, low-volume shops.

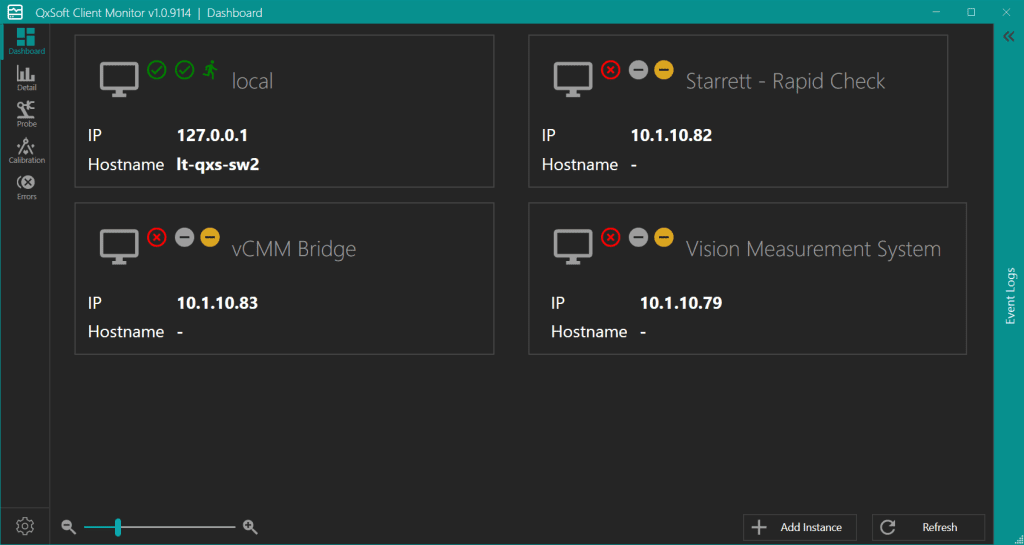

🌐 Multi-Site or Multi-Machine Oversight – Centralize visibility if you have CMMs in different departments, buildings, or even locations.

📈 Performance & Utilization Tracking – Track uptime, usage patterns, and cycle times. Justify capital investments or staffing based on real data.

👤 Remote Support & Troubleshooting – Techs can diagnose or help resolve issues without being physically present.

This standalone companion application is free for users with active SSC

Connects to single or multiple CMM-Manager instances over company intranet. Monitor all company CMMs from a single easy to use, highly visual, dashboard. In addition to real-time monitoring, it’s also possible to configure push notifications for CMM Errors, out of tolerance report, and other status indicators.

⚠️ When It’s Most Useful

– You run multiple shifts or unattended operations.

– Your CMM is critical to production flow (e.g., parts must be inspected before shipment).

– You’re in a regulated industry (aerospace, medical, automotive) where traceability matters.

– You’re managing more than one CMM or have them in different locations.