CMM-Manager includes a full suite of advanced fitting algorithms and point filtering tools that are designed to handle both ideal geometric features and complex, imperfect real-world data. These are especially useful when your measured point set contains outliers, noise, or surface defects, and when you want the feature fit to truly match the intent of the drawing or GD&T callout.

CMM-Manager is PTB-certified for its geometric fitting algorithms, meaning they’re verified against an internationally recognized standard for accuracy.

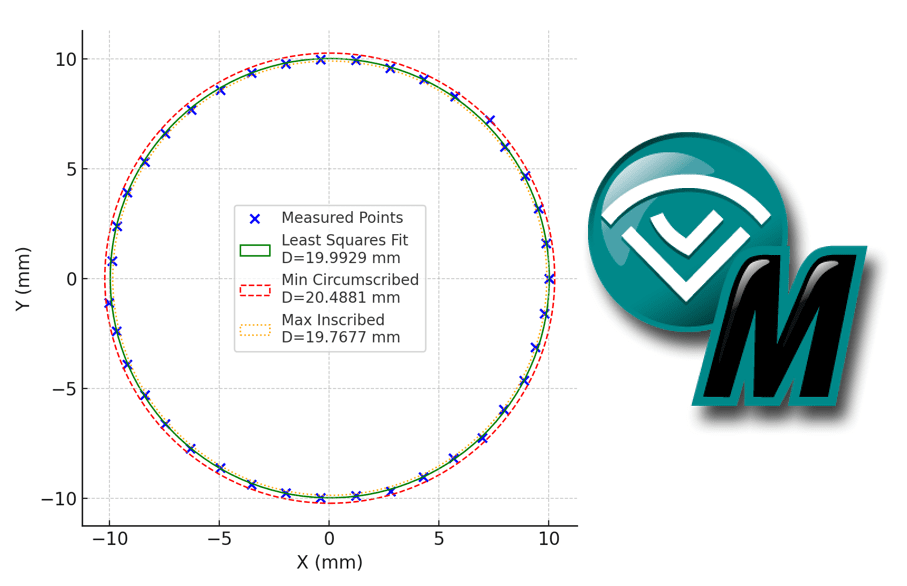

You can choose the method that best matches the GD&T requirement or inspection strategy:

- Least Squares (LSQ)

Minimizes the sum of squared distances from all points to the feature.

Best for when measurement noise is random and you want an “average” fit. - Minimum Zone / Chebyshev Fit

Fits the feature to minimize the maximum deviation (used for form tolerances like flatness, straightness).

Ideal for high-precision applications where extreme points must be controlled. - Maximum Inscribed / Minimum Circumscribed

Fits circles or cylinders to enclose or be enclosed by all measured points (used for size per ASME/ISO definitions).

Common for pin/hole gauges, bearing fits, etc.

Point Filtering & Outlier Control

Typical sources of outlier or point data includes:

- Burrs

- Dirt/oil spots

- Reflection or probe deflection anomalies

CMM-Manager gives you tools to filter these before the fit is calculated:

- Automatic Sigma Filtering

Removes points that deviate beyond a set standard deviation threshold. - Range Filtering

Rejects points outside a fixed tolerance band from an initial fit. - Directional Filtering

Useful for surfaces with intentional steps, chamfers, or edges where certain vectors should be ignored.

Why This Matters

- You can match the fit algorithm to the functional requirement of the part – avoiding measurement bias.

- Outlier filtering means better repeatability and less sensitivity to surface contamination.

- PTB certification gives traceability — important for audits and customer confidence.