Background

In dimensional inspection, fixturing is often treated as an afterthought. Yet, how a part is held during inspection can have as much impact on accuracy and repeatability as the CMM itself. Poorly designed or inconsistent fixturing leads to wasted setup time, unreliable measurements, and unnecessary downtime. For manufacturers under constant pressure to deliver precise results quickly, fixturing becomes both a mechanical and digital challenge.

The Challenge

Operators need two things from fixturing:

- Mechanical consistency – The fixture must locate the part in exactly the same way, every time, to remove variability.

- Programming foresight – The fixture must also be represented in the software environment so programmers can anticipate obstructions, plan efficient probe paths, and avoid collisions.

Too often, shops focus only on the physical side. While a solid fixture ensures the workpiece is stable, programmers working without virtual fixture models face costly trial-and-error. This can mean broken styli, wasted programming hours, or worse… scrapped parts.

The Solution with CMM-Manager

CMM-Manager addresses both halves of the fixturing equation.

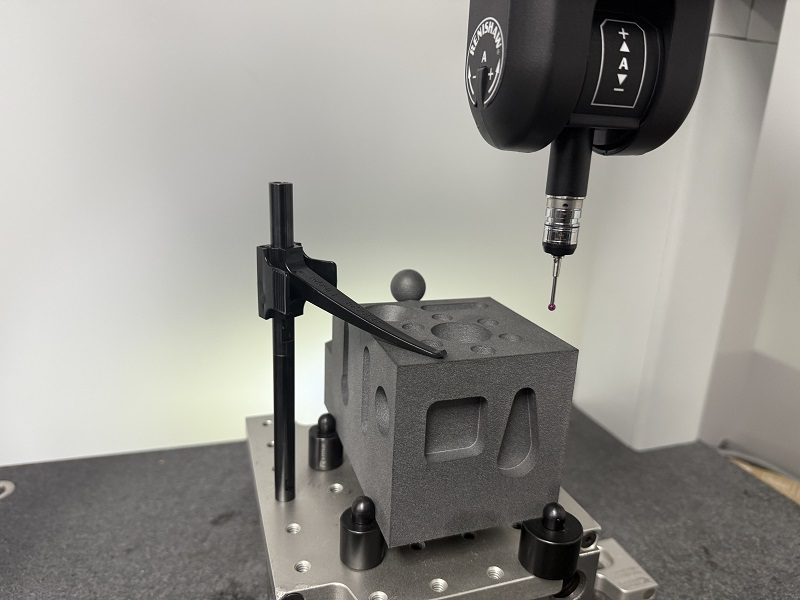

- Mechanical Stability

- A robust, repeatable fixture provides the foundation. Locating pins, clamps, and modular fixture systems ensure the workpiece is presented to the CMM in a controlled, repeatable orientation.

- With the right fixture, variation due to setup is virtually eliminated, allowing operators to focus on inspection rather than chasing alignment issues.

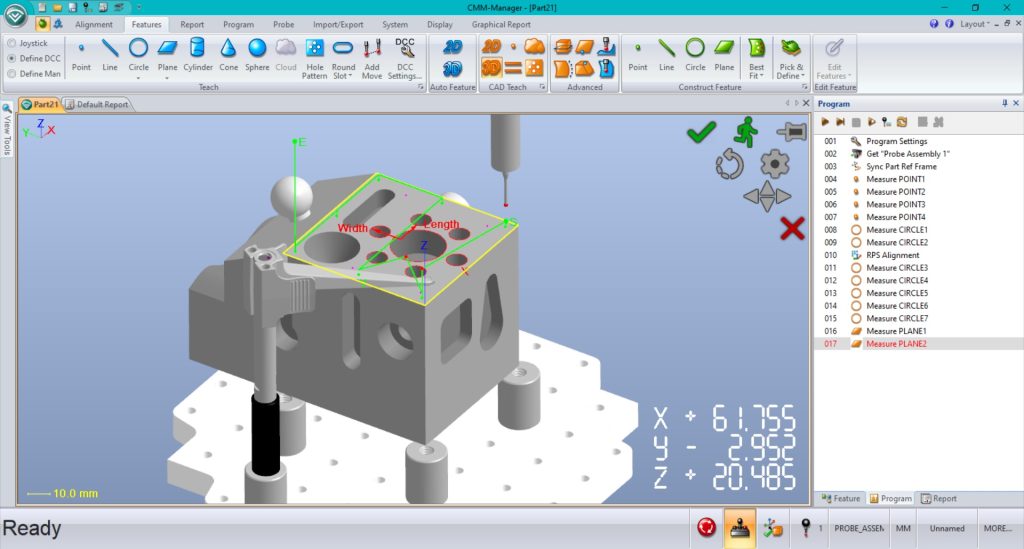

- Virtual Validation with CAD “Furniture”

- CMM-Manager enables programmers to import 3D CAD models of fixture components – referred to as “furniture.”

- These models become part of the inspection environment, letting programmers visualize exactly how the part will be presented on the machine.

- Path-planning tools take this into account, automatically generating probe paths that respect fixture geometry and avoid collisions.

- The result is fewer surprises on the shop floor, faster programming, and more efficient inspection routines.

Results

In practice, companies using CMM-Manager to combine mechanical fixturing with virtual “furniture” report:

- Reduced Downtime – Less time spent trialing probe paths on the machine.

- Improved Repeatability – Reliable, consistent part setups that minimize operator variation.

- Higher Throughput – Programs developed offline run smoothly with minimal adjustment.

- Lower Cost of Errors – Reduced risk of probe crashes, stylus wear, or fixture interference.

Conclusion

Fixturing is more than just a clamp or a plate, it’s a system for accuracy and efficiency. By combining solid mechanical workholding with virtual fixturing inside CMM-Manager, manufacturers achieve both consistency and foresight. The ability to import CAD models of fixtures, visualize them as “furniture,” and incorporate them directly into path planning ensures that inspection programs are not only accurate but also practical and production-ready.

CMM-Manager transforms fixturing from an overlooked necessity into a strategic advantage.

Looking to purchase modular CMM fixturing? We’ve partnered with Phillips Precision. Contact their sales team here – sales@phillips-precision.com

Learn more about the specific benefits of Phillips Precision products here – Considerations of Proper Inspection Fixturing – Inspection Arsenal