BTM Corporation

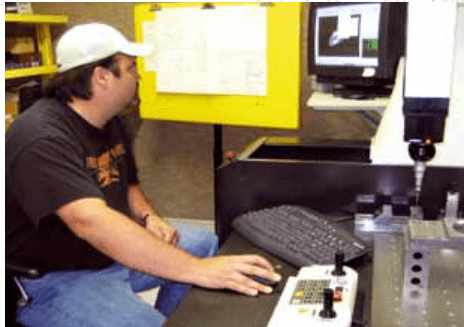

Michigan-based tool maker BTM Corporation opted for QxSoft’s user-centric CMM-Manager software to automate serial inspection on different CMM brands. BTM quality technicians also rely on CMM-Manager’s walk-in measurement capability to quickly take points on prototype and first-part articles. Parts designed and produced by BTM serve process automation at automotive and other manufacturers.

To increase tactile inspection efficiency, tool maker BTM Corporation uses intuitive CMM-Manager software in replacement of CMM proprietary software.

• Ideal to quickly take points on prototype and first-part articles

• 50% time reduction in automating serial inspection

on different CMM brands

• Digital graphic reports provide instant feedback that

streamlines customer interaction

A single software driving multiple CMM brands

“We have our hands full with quality control of diverse clamps, grippers, presses and locators for Chrysler, Ford, GM, Magna, Whirlpool and many other manufacturers worldwide,” says George Croll, Quality Manager for BTM Corporation in Marysville, Michigan. “We used the proprietary software of our Mitutoyo and Brown & Sharpe CMMs for some years, but we needed to increase our inspection efficiency by utilizing a single straightforward software tool that supports both CMM brands.”

Mr. Croll explains that he researched different CMM software packages and identified CMM-Manager as the solution of choice. “Although the majority of CMM software packages offer all the trimmings you need, most software packages lack an intuitive feel. This is why CMM Manager made the difference.”

Performing instant walk-in measurement

In many instances, BTM quality technicians simply want to take a few

measurements on prototype or first-part articles to feedback data

to engineering or production. The intuitive CMM-Manager interface

enables them to quickly align the part and measure planes and geometric

features, such as hole patterns. They take snap point measurements on

the screen, which almost totally eliminate manually probing the work

pieces, to create dimensional charts that indicate size, geometry, and

position information on the spot.

The software offers the opportunity to define color-coded marks that

highlight point deviation before wrapping up the graphic report which

can be passed on to the customer. “The software is very easy to use,”

remarks Croll. “I would recommend CMM-Manager to any metrology

system user who cares about measurement productivity. Even before

attending any training sessions, we already figured out how to use most

of the features the software offers”

Save time through CAD-based serial inspection

When producing small or larger series of rotary actuator or clamp piston pieces, for example, we follow a different inspection strategy,” explains Croll. “First, we load the SolidWorks CAD file of the part into the CMM-Manager software and subsequently pick the positions and features that we want to have measured. We simply click a point or feature on a 3D view of the part, and drag-and-drop the icon in the part program representation. A smart software capability of CMM-Manager is the automatic conversion of the part program into a collision-free touch probe motion path including optimum probing angles to measure deep pockets or through holes, for example.”

Croll confirms that this interactive Pick-Confirm-and-Measure method is much more straightforward, time-efficient and error-proof than coding probe paths and angles manually. “As a result, BTM inspectors only spend half the time preparing new measurement routines and spend much less time on serial inspection. Instead, they focus on metrology work that really matters, such as defining and evaluating inspection reports. Overall, CMM-Manager is more user-friendly than any other package that we have used so far. And through graphic part-to-CAD comparison, CMM-Manager is a better communication tool for us in timely resolving technical issues with our customers”