High-Precision is required in the manufacture of riflescopes and spotting scopes where repeatable optics are critical.

“PH20 Probe Head gave us the throughput that we currently needed for our production requirements.” CMM-Manager helps to facilitate this throughput by creating efficient probe paths and reducing programming time and effort.”

Nightforce Optics is headquartered in the small town of Orofino, Idaho along the famous Clearwater River. But that is the only small reference that can be said for this twenty-eight-year- old company that jumped into the highly competitive precision shooting market with the goal of building the best riflescopes in the world. That goal has turned into reality as the company continues to excel with advanced manufacturing and testing technologies.

Scott Johnson, quality manager for Nightforce Optics says, “Our approach continues to be designing and building top-of-the-line optics from the ground up. We serve the needs of military special forces, law enforcement agencies, serious competitive shooters and hunters who need the most dependable and best performing optics available. Much of the product line is hand assembled in the Orofino production facility. 100% of these products undergo a rigorous 70-point quality checklist that tests

and verifies that each ach product meets the highest standards for quality and functional accuracy before leaving the facility”.

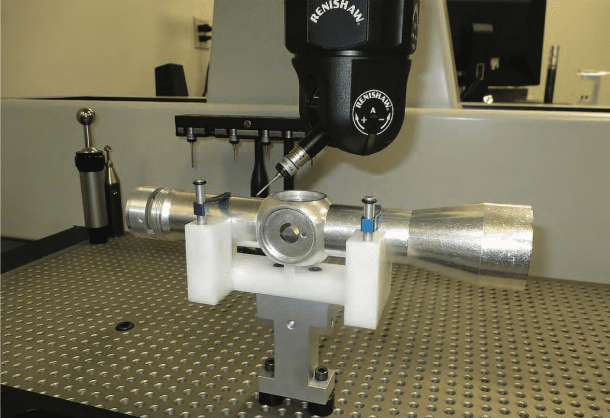

Johnson explains, “Riflescopes have a wide range of precision mating parts that are all crucial to the accuracy and performance of each product. For example, our scope body tubes are made from aerospace aluminum bar stock and machined by specially designed CNC multi spindle lathes. We also use complicated multiple start thread designs with very tight tolerances in adjustment parts that require thorough inspections using custom made calibrated gages to ensure precision in each moving part. In addition, we perform ‘first article’ inspections that require proper documentation along with in-line inspections during the production run of parts to ensure the parts conform to the design requirements. As the expanding need for accurate and documented quality inspections is required, you need to have the best measuring equipment.”

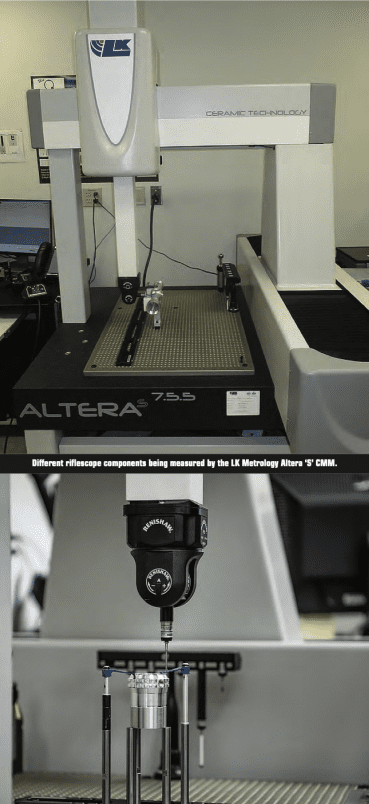

Johnson further explains, “When I first came to Nightforce Optics it was obvious we needed to reinforce our Coordinate Measuring (CMM) capabilities. Over the years, CMM technology has vastly improved and we wanted to expand our measuring capabilities. We needed five-axis capability with a Renishaw PH20 probe head that gave us the throughput that we currently needed for our production requirements. The PH20 probe head gave us the touch-trigger capability for fast, infinite rotary positioning for high-speed point capture with minimal CMM movement. The question then was, whose CMM would be the best fit for us. We talked to a variety of CMM builders and

agreed LK Metrology’s Altera ‘S’ 7.5.5 five axis CMM best fit our needs. We needed a modification of the CMM platform to be able to fit it into our temperature-controlled inspection laboratory, and LK Metrology was willing to work with us to meet our needs. They were willing to match a configuration with our stated desires and modify a standard set-up while supplying the necessary accuracies.

In the process, LK Metrology demonstrated the CMM Manger software of the CMM and proved its capability with the PH20 probe head.”